Understanding **Thermal Transfer Label Printers**: A Comprehensive Guide

In the evolving landscape of business and technology, thermal transfer label printers have emerged as indispensable tools for many industries. These printers are renowned for their ability to produce high-quality, durable labels quickly and efficiently. In this article, we will delve deep into the workings of thermal transfer label printers, their benefits, applications, and much more, equipping you with insights to leverage this technology for your business needs.

What are Thermal Transfer Label Printers?

Thermal transfer label printers are specialized printing devices that use heat to transfer ink from a ribbon onto a label substrate. Unlike direct thermal printers, which rely on heat-sensitive media, thermal transfer printers produce high-resolution images that are more resistant to fading, moisture, and abrasion.

How Do Thermal Transfer Label Printers Work?

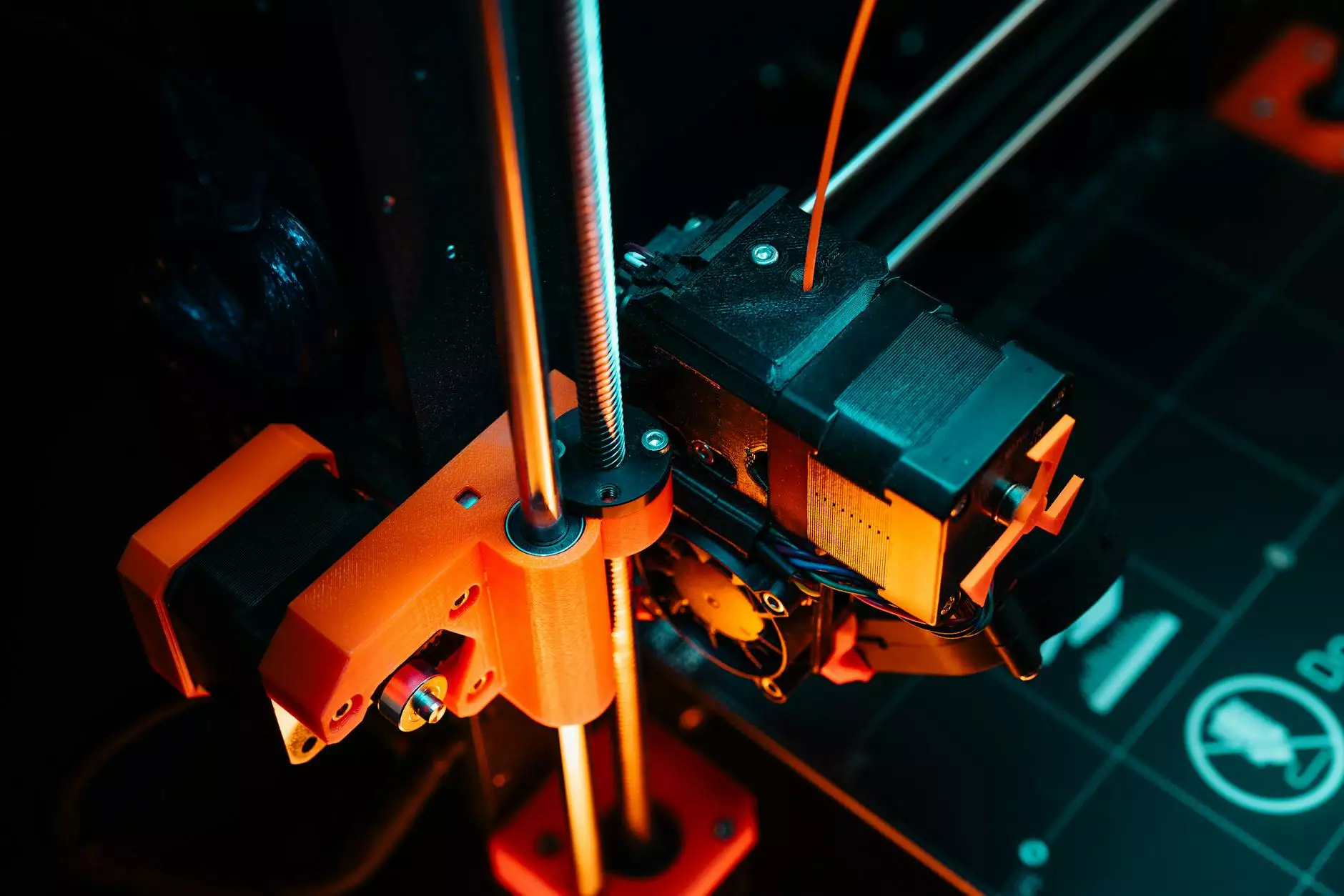

The mechanism of a thermal transfer label printer involves several key components:

- Print Head: This is where the heat is generated, melting the ink from the ribbon to transfer it onto the label material.

- Ink Ribbon: A colored ribbon containing wax or resin that melts under heat and is transferred onto the label.

- Label Stock: The surface material that receives the printed image, which could be paper, plastic, or synthetic materials.

The process begins when a label design is sent to the printer. The printer uses thermal elements in the print head to activate specific areas of the ink ribbon. As the ribbon passes over the label stock, the heat melts the ink and adheres it to the label, resulting in a clear and durable print.

Benefits of Using Thermal Transfer Label Printers

Investing in thermal transfer label printers offers numerous advantages for your business operations. Here are some of the key benefits:

- High-Quality Prints: The output is sharp and resilient, great for barcodes, graphics, and small text.

- Durability: Labels produced are resistant to smudging, scratching, and fading, ensuring longevity.

- Versatility: These printers can handle a wide range of label materials, catering to various applications, from shipping labels to product labels.

- Efficiency: With rapid printing speeds, thermal transfer printers can meet the high demands of fast-paced business environments.

- Cost-Effectiveness: While the upfront investment may be higher than some alternatives, the quality and longevity can lead to lower long-term costs.

Applications of Thermal Transfer Label Printers

Thermal transfer label printers serve a wide spectrum of industries. Here are some notable applications:

1. Manufacturing and Warehousing

In manufacturing and warehousing, accurate and durable labeling is paramount. Thermal transfer label printers are used for: - Product labeling - Shipping labels - Inventory management These labels provide essential information, including barcodes and product details, facilitating streamlined operations.

2. Retail

Retail businesses utilize thermal transfer printing for: - Price tags - Product labels - Promotional items The high-quality prints are essential for consumer appeal and can withstand the rigors of retail environments.

3. Healthcare

In the healthcare sector, where accuracy is critical, thermal transfer label printers are employed for: - Patient identification - Medication labeling - Asset management These applications require precision and durability, making thermal transfer printers an ideal choice.

Choosing the Right Thermal Transfer Label Printer

When selecting a thermal transfer label printer, several factors should guide your decision-making process:

- Print Resolution: Higher resolution printers yield better quality images, essential for detailed or small text.

- Print Speed: Assess the volume of labels you need to produce. Faster printers are better suited for high-demand environments.

- Connectivity Options: Ensure the printer has suitable connectivity options for your business environment, such as USB, Ethernet, or Wi-Fi.

- Label Size Compatibility: Consider the sizes and types of labels you will be using to ensure the printer can accommodate them.

- Cost of Ownership: Factor in the cost of consumables like ribbons and labels, as well as maintenance and support services.

Conclusion

In conclusion, thermal transfer label printers represent a significant advancement in label printing technology. With their ability to produce durable, high-quality labels rapidly, they have become essential tools across various industries, including manufacturing, retail, and healthcare. Understanding their benefits, applications, and factors to consider when purchasing a printer is crucial for making informed decisions that can enhance your business operations.

As your business seeks to maximize efficiency and effectiveness in labeling processes, investing in thermal transfer label printers can be a transformative step. For further information about the best thermal transfer label printers, you can explore the offerings at omega brand, where we combine expert knowledge with industry-leading products.